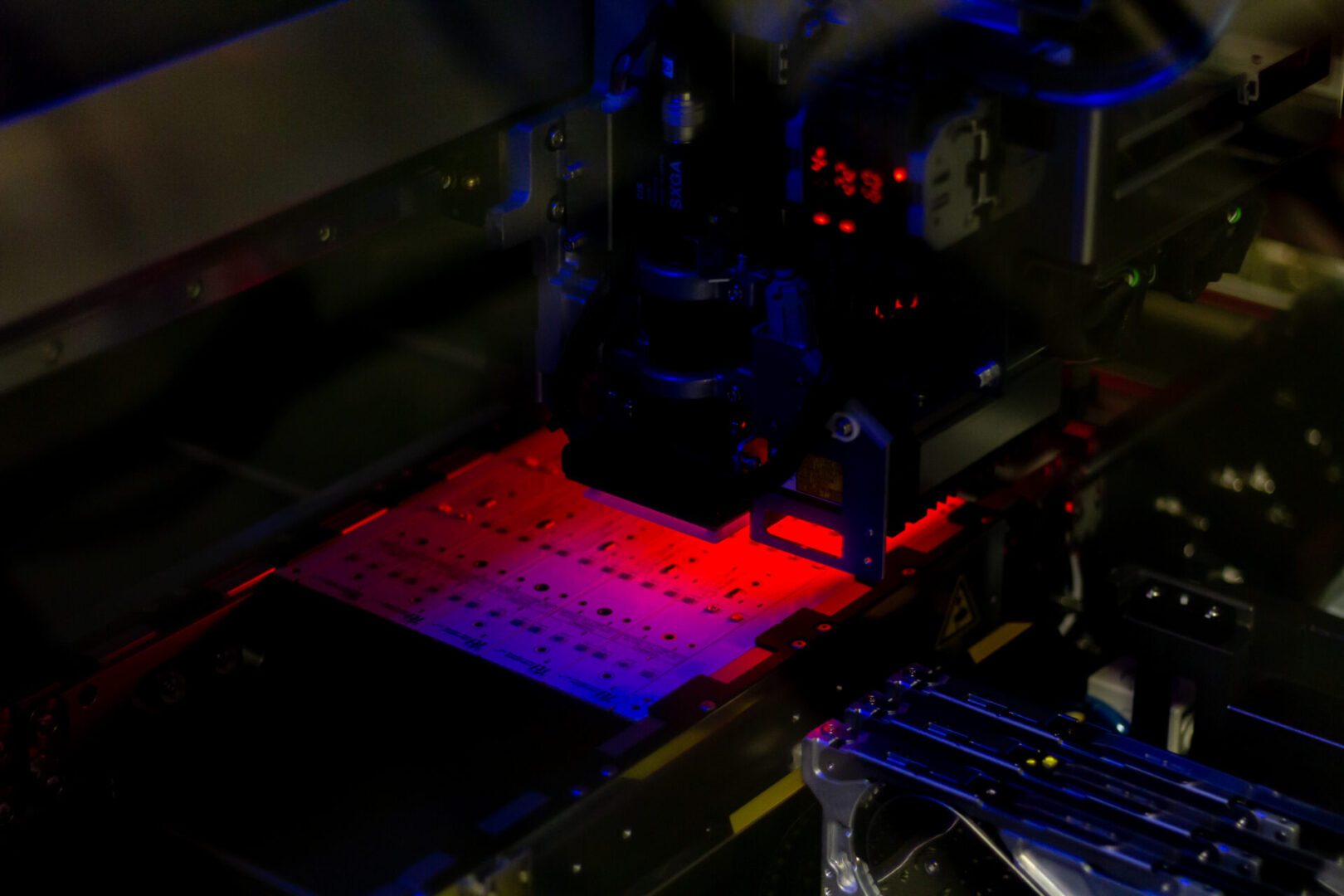

High-Grade Electronic Manufacturing Equipment

Equipment

CM Solutions, Inc. has all of the industry-standard equipment required to meet your needs. From Universal THT placement equipment to the JUKI-FUJI SMT production lines, your product can be produced with precision and efficiency.

During and after production, CM Solutions offers many options to verify and test your product, as well. Automatic Optical Inspection (AOI) machines and X-Ray capabilities are available, along with an Agilent 3070 In-Circuit Test (ICT) platform.

Production Equipment

SMT:

-

JUKI / FUJI SMT Placement

-

DEK Screen Printers

-

FUJI SMT Placement Systems

-

BTU Reflow Ovens (with profiling)

-

Big Board Capabilities

THT:

-

Universal Instruments THT Placement Systems

-

THT Lead Preparation

-

Scalable Hand-Load Lines

-

Solder Masking

-

(2) Lead-Free & (1) Leaded Solder Wave

-

Aqueous & No Clean Processing

-

Conformal Coating

Production Equipment

SMT:

-

5 SMT Lines

-

DEK Screen Printers

-

FUJI SMT Placement Systems

-

BTU Reflow Ovens (with profiling)

THT:

-

Universal Instruments THT Placement Systems

-

THT Lead Preparation

-

Scalable Hand-Load Lines

-

Solder Masking

-

Selective Solder

-

(2) Lead-Free & (1) Leaded Solder Wave

-

Aqueous & No Clean Processing

-

Conformal Coating

Verification & Test Equipment

-

X-Ray Inspection

-

RF Isolation (Faraday Cage)

-

Functional Test

-

Agilent 3070 In-Circuit Test (ICT)

-

Hakko Computer Controlled BGA rework station

Box Build:

-

Solid State Laser Engraver for metals and plastics

-

Branson 2000 Ultrasonic Welder

-

Custom assembly fixture options available.